Manufacturer Plastic Zipper with 3# Silver Open End

Product Main Parameters

| Material | Polyester/Nylon |

|---|---|

| Place of Origin | Haining, Zhejiang |

| Teeth Type | Customized |

| Color | Customized |

| Zipper Type | Open End |

| Brand Name | ABS |

Common Product Specifications

| Size | 3# |

|---|---|

| Length | Customized |

| Slider | Customized Puller |

| Logo | Customized |

Product Manufacturing Process

The manufacturing process of plastic zippers involves precise engineering to create durable and flexible fastening solutions. Initially, high-quality polymers such as nylon or polyester are selected for their strength and pliability. The process begins with the creation of zipper tapes, to which rows of interlocking teeth are attached via a precise molding or coiling technique. Advanced machinery ensures uniform tooth alignment and secure attachment to the fabric tape. After teeth are affixed, sliders are positioned to facilitate the opening and closing mechanism. Continuous quality checks are integral, ensuring each zipper meets international standards. The process concludes with customizations such as coloring and branding, enhancing the final product's aesthetic appeal while maintaining functionality. This comprehensive approach by manufacturers guarantees a reliable product line that meets diverse consumer needs.

Product Application Scenarios

Plastic zippers are indispensable in various sectors due to their adaptability and resilience. In the fashion industry, their lightweight and versatile nature makes them ideal for garments like jackets, trousers, and dresses, providing functional yet stylish fastening solutions. Outdoor equipment manufacturers value these zippers for their resistance to environmental elements, making them suitable for products such as tents, sleeping bags, and backpacks. In the home textile sector, plastic zippers enhance the usability of pillow covers and duvet sets. This versatility, combined with cost-effectiveness, establishes plastic zippers as essential components across multiple industries, aiding in the creation of products that balance practicality with design innovation.

Product After-Sales Service

Our customer-centric approach ensures satisfaction with each product sold. We offer comprehensive after-sales support, including replacement services for defectively manufactured items and technical assistance for installation or usage queries. Our dedicated service team is available 24/7 to address any concerns, providing solutions promptly and efficiently to maintain high customer satisfaction levels.

Product Transportation

Our logistics network guarantees secure and timely delivery worldwide. We utilize environmentally friendly packaging materials to protect each product during transit, aligning with our commitment to sustainability. Our partnerships with leading shipping services enable us to offer expedited delivery options, ensuring that customers receive their products within stipulated timelines.

Product Advantages

- Customizable for diverse needs

- Corrosion-resistant

- Lightweight design

- Aesthetic versatility with multiple color options

Product FAQ

- What materials are used in your plastic zippers? Our manufacturer plastic zippers are made from durable nylon or polyester, selected for their strength and flexibility.

- Can I customize the color and length? Yes, we offer extensive customization options, including color and length, to fit your specific requirements.

- Are the zippers corrosion-resistant? Indeed, plastic zippers are designed to resist rust and corrosion, making them suitable for outdoor and high-moisture environments.

- What is the minimum order quantity? Our minimum order quantity varies; please contact our sales team for detailed information.

- How do you ensure zip quality? Our zippers undergo rigorous quality checks during production, adhering to European and American standards.

- What applications are suitable for your zippers? Our plastic zippers are versatile, suitable for clothing, bags, tents, and more.

- Where are your products manufactured? Our products are manufactured in our modern facility in Haining, Zhejiang.

- Can I order samples? Yes, we provide free samples to help you assess our product quality.

- Do you support OEM and ODM services? Absolutely, we welcome both OEM and ODM orders to meet unique customer needs.

- What are your shipping options? We offer worldwide shipping with various options, including express delivery for urgent orders.

Product Hot Topics

- Why choose manufacturer plastic zippers over metal ones? Manufacturer plastic zippers offer several advantages over metal zippers, such as being more cost-effective, lightweight, and resistant to rust and corrosion. These attributes make them particularly suitable for use in environments exposed to moisture or chemicals. Furthermore, their ability to be dyed in various colors provides more design flexibility, allowing both functionality and aesthetic appeal to be achieved in products. Many of our clients report increased satisfaction due to these characteristics, making plastic zippers a popular choice across different industries.

- How does customization benefit the end user? Customization offers the end user a tailor-made solution that enhances product usability and market appeal. By choosing personalized colors, logos, and lengths, manufacturers can align the zippers with their brand identity and consumer preferences. This flexibility enables better integration into fashion lines, equipment designs, or specialized applications, vastly improving the end-user experience. High levels of customization also reflect a company’s dedication to meeting diverse client needs, fostering brand loyalty and satisfaction among consumers.

- What makes plastic zippers environmentally conscious? Plastic zippers are considered more environmentally conscious when they incorporate sustainable practices throughout their lifecycle. This includes using recycled materials, adopting energy-efficient manufacturing processes, and supporting recycling programs. Biodegradable plastic options and eco-friendly packaging are also steps towards reducing environmental impact. Companies committed to these practices contribute positively to sustainability, helping to preserve resources and reduce waste in the long term. Consumers increasingly value these eco-conscious approaches, influencing purchasing behaviors and brand perceptions.

- Insights into the durability of manufacturer plastic zippers Manufacturer plastic zippers are engineered for durability, ensuring they withstand regular use and harsh conditions. The materials and manufacturing techniques employed provide robust teeth and tapes that resist breakage and wear. Longevity is a crucial consideration for applications in outdoor gear, luggage, and apparel, where zippers face stress and friction. Our clients commend the reliability and performance of our plastic zippers, affirming their suitability for demanding environments and contributing to extended product lifespans.

- The versatility of manufacturer plastic zippers Plastic zippers manufactured by experienced companies like ours are incredibly versatile. They are used across various industries, from fashion and accessories to industrial and outdoor equipment. The ability to customize and adapt to unique specifications makes them an essential component for designers worldwide. Their lightweight nature, coupled with robust performance, allows for seamless incorporation into diverse products, enhancing both functionality and design efficiency. Versatility remains a key selling point as industries evolve and consumer needs become more complex.

- How technological advancements are shaping the zipper industry Technological advancements have significantly influenced the zipper industry, leading to enhanced product capabilities and new material innovations. Modern manufacturing equipment allows for precise and efficient production, accommodating intricate designs and custom orders with ease. Additionally, the development of smart zippers featuring integrated technology for security or connectivity reflects a growing trend towards multifunctional products. These innovations ensure that zippers remain relevant and adaptable in a rapidly changing market, meeting the evolving demands of consumers and industries alike.

- Choosing zippers for extreme environments Manufacturer plastic zippers are often selected for extreme environments due to their inherent properties, such as corrosion resistance and durability. These zippers perform reliably in high-moisture, high-salt, or chemical-exposed settings, making them ideal for marine gear, outdoor apparel, and industrial applications. Their lightweight yet robust construction offers a balance of performance and ease of use, ensuring products remain functional under challenging conditions. Users benefit from the dependability and longevity of these zippers, which protect and enhance valuable goods in harsh environments.

- The role of plastic zippers in modern design In modern design, plastic zippers play a critical role by offering both functional and aesthetic advantages. Their adaptability in color, shape, and finish allows designers to integrate them seamlessly into diverse products. This flexibility supports creative expression, enabling designers to innovate while maintaining product functionality. The cost-effectiveness of plastic zippers also ensures that design goals are achieved without compromising budgetary constraints. As trends shift towards minimalistic and sustainable designs, plastic zippers continue to meet industry needs through their versatile applications.

- Plastic zippers and consumer safety standards Compliance with consumer safety standards is a priority for manufacturers of plastic zippers. Ensuring that materials used are non-toxic and phthalate-free aligns with global safety requirements, providing peace of mind for consumers. Rigorous testing and quality assurance processes confirm that zippers meet or exceed these standards, safeguarding users from potential hazards. Adherence to safety protocols reinforces brand reputation and trust, highlighting a manufacturer’s commitment to consumer welfare and product excellence across markets.

- Future trends in the manufacturer plastic zipper market The future of the manufacturer plastic zipper market is poised for growth, driven by technological innovations and sustainable practices. Emerging trends point towards increased demand for eco-friendly products and smart zippers with integrated features like security or connectivity. Moreover, advancements in materials science may lead to the development of even more durable and versatile zippers. Manufacturers that embrace these trends and continue to innovate are likely to maintain competitive advantages, catering to an environmentally conscious and tech-savvy consumer base. Adaptation and foresight will be vital in harnessing these opportunities effectively within the industry.

Image Description

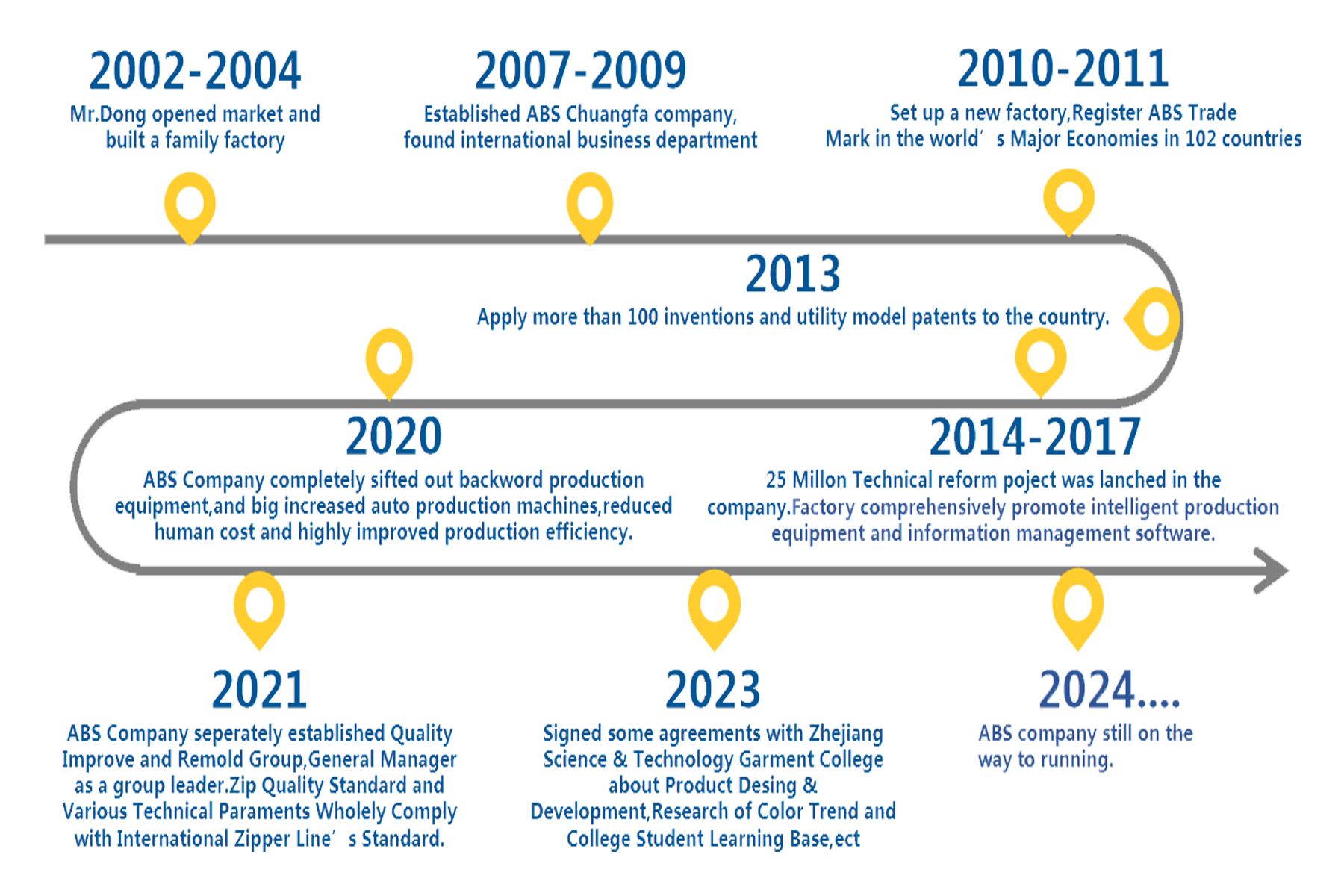

ABS Company Introduction

ABS Zhejiang Chuangfa Zipper Technology Co., LTD. was founded in 2011,which is a professional company engaged in production,sale and service of Zippers and Buttons for more than 10 years.Our Factory located in Zhejiang Haining Industrial Zone,which beside Hangzhou and enjoy very convenient transportation--15 minutes to the railway station,60 minutes to Hangzhou Airport.Our main products are Zippers,buttons and hardware parts which are exported to worldwide,such as South and North America,Europe,Southeast and Africa.Our company brand--ABS is very famous at home and abroad.We registered trademark brand ABS in 102 countries.The scope of our product using is worldwide,which suitable for clothing,shoes and hats,bags,sofa,bedding,tents,sleeping bag,umbrella,travel supplies etc.

We welcome OEM and ODM orders.Our Intelligent production equipment to ensure the effectiveness of production,product quality to reach the European and American Standard. We fully integrates the current Internet thinking concept, integrates the resources of clothing colleges with creative and design institutions, and keeps the leading position in the zipper industry field through continuous innovation of products and services. It is a modern enterprise guided by the concept of win-win cooperation and mutual development.

Our Company Slogan is “Customer first,Brand first and Service first.”

Question 1 Has your factory been audited by any organizations or institutions?

Answer Yes.We have passed the certification of GB/T19001-2016 idt ISO9001:2015,OEKO-TEX100, GRS and TUV Factory Adult.

Question 2 How long does it take to get any feedback after submitting an enquiry?

Answer In general, we will get back to you within 12 hours on weekdays.

Question 3 What are the factors that will determine the quotation?

Answer The quotation depends on a variety of factors, inclusive of the materials, quantities, tapes, slider types, the techniques involved and so forth. Please inform us of your requirements in detail when you submit an enquiry so we could offer you the best quotation.

Question 4 What are your payment terms?

Answer L/C, T/T, PayPal and West Union are all acceptable to us .Please double check with us if you would like to change the payment method.

Question 5 Can you accept any customized design?

Answer Yes. Customized/custom-made design is acceptable, including the custom-made sliders/pullers/teeth, teeth colors, tapes with mixed colors,customized textures,custom buttons,etc.

Question 6 Can we customize the colors or sizes and print our own logo?

Answer Yes. Customized colors or sizes are acceptable. As for colors, Pantone Color Card, GCC Color Card, Taiwan Color Card are available for you to choose from. Additionally, we can design and print your logo as per your request.

Question 7 Can we request for a free sample?

Answer Regular samples can always be provided free of charge if they are available in stock.If not, additional sample/mould fees will be charged to proceed with the production. Customers are supposed to bear the freight charge, which can be refunded following the order confirmation when applicable. Please double check with us.

Question 8 What’s your average lead-time? How long will it take to receive our order?

Answer Generally speaking, samples take 3-5 days while 10-15 days is required for mass production upon confirmation of the order, plus the time required for shipment/delivery. As for the metal zippers used for jeans, mass production takes less than 10 days.

Question 9 What’s your manner of packing?

Answer Based on the international packing standards, the packing manners may vary from customer to customer. We will try our best to meet your requirements so long as they conform to the conventional packing methods

Question 10 How about Price Terms and Delivery?

Answer There are a lot of choices available, including FOB Shanghai/Ningbo, CNF, CIF, etc. Generally speaking, DDP will be applied to large orders, while FEDEX, UPS, DHL, TNT and EMS are applicable to small orders.