Fire Proof Zipper Supplier - Premium Protection Solution

Product Main Parameters

| Element | Description |

|---|---|

| Material | Metal |

| Teeth | Y Teeth |

| Teeth Color | Shiny Silver |

| Tape Material | Nomex |

| Slider | Auto Lock |

| Size | Customizable |

Common Specifications

| Specification | Detail |

|---|---|

| MOQ | 1500 pcs |

| Sample Offer | Free |

| Delivery Time | 7-10 days |

| Certification | ISO/GRS/OEKO-TEX Standard 100 |

Product Manufacturing Process

The production of fire proof zippers involves critical steps to ensure the highest standards of safety and durability. The process begins with selecting metals like brass or nickel for their melting point and heat resistance. Aramid fibers such as Kevlar are incorporated for added strength and temperature resistance. Nomex is used for the zipper tape to withstand high temperatures and flames. The assembly process ensures tight interlocking of the metal teeth, and rigorous testing is conducted to confirm fire resistance in accordance with industry standards. This meticulous approach guarantees that our fire proof zippers meet the requirements of high-risk industries, providing reliable safety and performance.

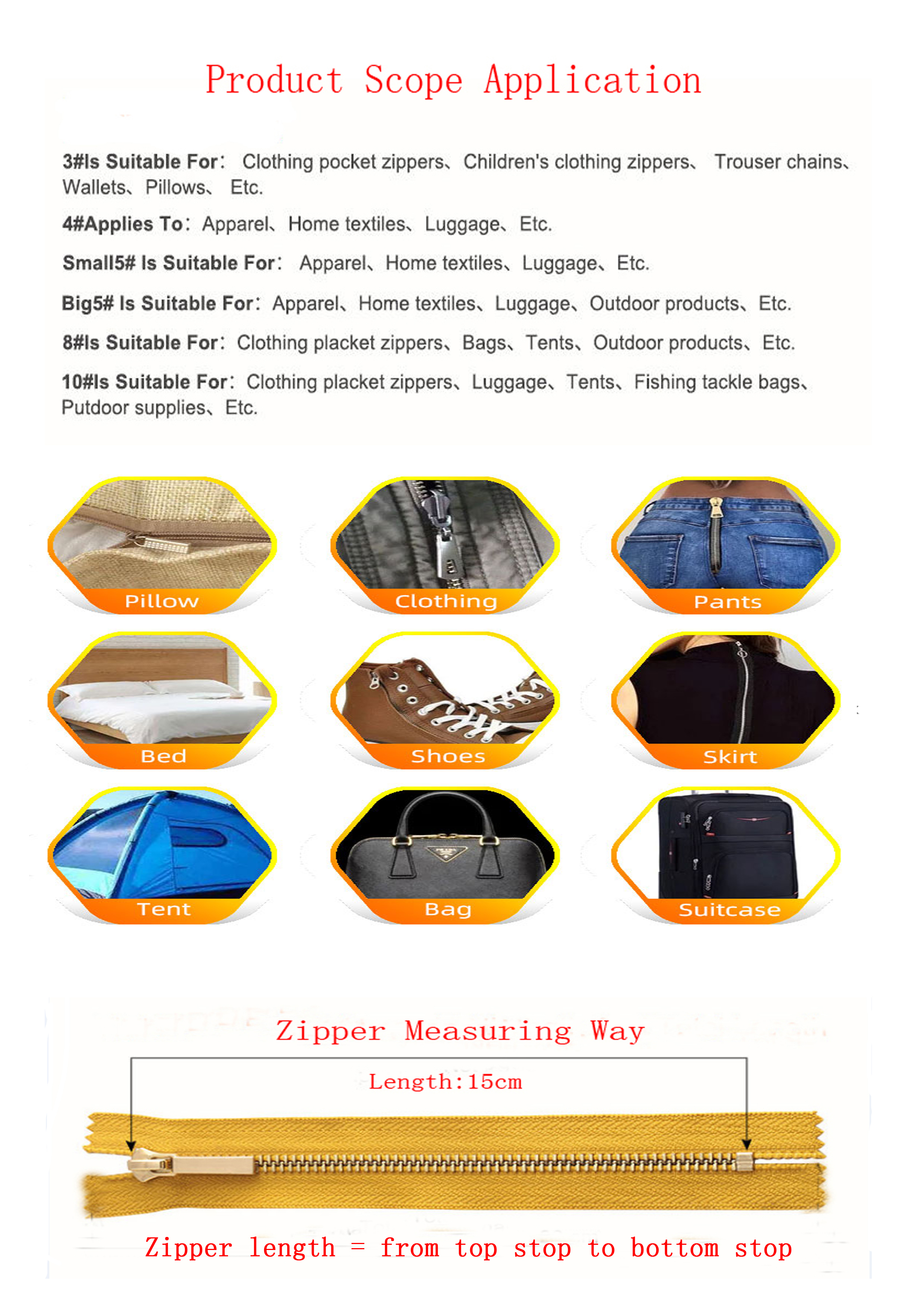

Product Application Scenarios

Fire proof zippers are essential in scenarios where fire safety is paramount. In firefighting gear, these zippers are vital to protect users from severe burns and injuries during firefighting operations. In the military and aviation sectors, uniforms equipped with fire proof zippers protect personnel against potential exposure to flames resulting from explosions. Industrial applications in oil, gas, and chemical industries utilize these zippers for protective clothing, ensuring safety during high-temperature operations. The aerospace industry also relies on fire proof zippers in space suits and shuttle interiors, needing materials that stand up to extreme temperature and pressure variations, ensuring both safety and durability.

Product After-Sales Service

Our supplier provides comprehensive after-sales support, offering a free repair or replacement policy within 1 year if any defect is found in the fire proof zippers. Our dedicated customer service team is available 24/7 to address any issues or concerns. We also offer guidance on installation and usage to ensure optimal performance of our zippers. We are committed to ensuring customer satisfaction by providing timely and effective solutions to any post-purchase concerns.

Product Transportation

Our fire proof zippers are securely packaged to prevent damage during transit. We provide fast delivery options, ensuring that orders reach global destinations promptly. Customers can track their shipment online with ease. We collaborate with reputable logistics partners to offer reliable shipping solutions, ensuring that our products arrive in perfect condition.

Product Advantages

- Highly resistant to fire and extreme temperatures.

- Durable construction for prolonged use in demanding environments.

- Meets international safety standards for maximum reliability.

- Available in customizable sizes to suit various applications.

- Efficient supply chain for timely delivery worldwide.

Product FAQ

What materials are used in fire proof zippers?

Our fire proof zippers are crafted from high-temperature resistant metals like brass, nickel, or aluminum for the teeth, combined with Nomex tape and Kevlar fibers. This combination ensures superior fire resistance and durability, making them suitable for high-risk environments.

How do fire proof zippers enhance safety?

Fire proof zippers are designed to resist ignition and withstand high heat. They prevent garment failure in critical scenarios, providing an extra layer of protection in firefighting, military, industrial, and aerospace applications, ensuring wearer safety.

Where can these zippers be applied?

They are widely used in firefighting apparel, military uniforms, industrial safety clothing, and aerospace suits. Their high resistance to heat and fire makes them suitable for scenarios demanding enhanced safety measures.

Are the zippers customizable?

Yes, we offer customizations in size and design to meet specific requirements of different industries. Clients can specify dimensions and colors to match their unique needs while maintaining safety standards.

What certifications do these zippers have?

Our fire proof zippers comply with ISO, GRS, and OEKO-TEX Standard 100 certifications, confirming their safety, quality, and environmental friendliness. These certifications assure users of their reliability and compliance with industry standards.

What is the delivery time for orders?

We offer a prompt delivery service, with an order fulfillment time of 7-10 days. Our strategic partnerships with logistics providers ensure that our products are delivered to clients worldwide within the stipulated timeframe.

Is there a sample policy?

Yes, we provide free samples to prospective buyers, allowing them to assess the quality and functionality of our fire proof zippers before making bulk orders. This ensures satisfaction and trust in our products.

How do you ensure product quality?

We employ advanced testing equipment and a meticulous quality control process to ensure each zipper meets our high standards. Our R&D team is constantly innovating to improve product performance and safety.

Can you support OEM/ODM orders?

Yes, we specialize in OEM and ODM services, allowing clients to commission custom designs that align with their brand and functional requirements. We work closely with clients to turn their concepts into reality.

What is your after-sales service policy?

We offer a 1-year warranty covering repairs or replacements for any defects. Our support team is available 24/7 to assist with any issues, ensuring your satisfaction and continuous use of our products.

Product Hot Topics

Why is fire safety essential in product design?

Fire safety in product design is critical for protecting lives and assets in environments prone to high temperatures or flames. This consideration is especially vital in sectors like firefighting, aviation, and industrial manufacturing, where exposure to fire and heat is common. At our company, we prioritize incorporating fire-resistant materials into our products, including our fire proof zippers, to ensure the highest levels of safety and reliability. By doing so, we help mitigate the risk of burns, injuries, and catastrophic losses, thereby enhancing consumer confidence and trust in our supplier capabilities.

How does innovation impact fire proof zipper manufacturing?

Innovation plays a crucial role in advancing the quality and effectiveness of fire proof zippers. Through research and development, we continuously explore new materials and manufacturing techniques that enhance fire resistance and functionality while maintaining cost-effectiveness. These innovations enable us to improve the performance of our products, ensuring they meet the evolving demands of modern safety standards. Our relentless pursuit of innovation allows us to remain a leading supplier in the industry, offering cutting-edge solutions that prioritize safety and reliability.

Are fire proof zippers only for professional use?

While fire proof zippers are predominantly designed for professional settings, such as firefighting gear or industrial uniforms, their applications are expanding into consumer products as well. As awareness of fire safety grows, more designers are integrating these zippers into everyday items like camping gear or outdoor apparel to enhance safety. This broader application demonstrates the versatility and critical importance of fire-resistant components in various sectors and underscores our position as a supplier of top-quality fire proof zippers for diverse markets.

What challenges exist in the production of fire proof zippers?

The production of fire proof zippers involves several challenges, including sourcing high-quality, fire-resistant materials and ensuring consistent manufacturing processes to maintain safety standards. Moreover, balancing the cost of production with the need for durable and effective zippers is critical. As a dedicated supplier, we constantly strive to overcome these challenges by investing in technology and innovation, ensuring that our products not only meet but exceed international safety requirements, providing our customers with reliable solutions.

How does the supplier ensure the sustainability of fire proof zippers?

Sustainability is at the core of our production philosophy. We prioritize eco-friendly practices, such as using recyclable materials and minimizing waste during manufacturing. By maintaining rigorous environmental standards, we ensure our fire proof zippers have a low impact on the environment while still delivering superior performance. As part of our corporate social responsibility, we are committed to sustainable development, thereby enhancing the reputation of our brand as a responsible supplier.

What technological advancements are influencing zipper design?

Technological advancements, such as the development of new heat-resistant materials and advanced manufacturing techniques, significantly influence zipper design. These innovations enable the creation of more efficient and resilient fire proof zippers. By leveraging cutting-edge technology, we can enhance the functionality and safety of our products, ensuring they meet the stringent demands of high-risk industries. As a forward-thinking supplier, we are committed to integrating the latest technology to improve our offerings continually.

Why choose a specialized supplier for fire proof zippers?

Choosing a specialized supplier like us ensures access to expert knowledge, premium-quality products, and dedicated customer support. We have a proven track record in producing reliable fire proof zippers that comply with international standards, making us a dependable partner for safety-focused businesses. Our customized solutions and after-sales services further distinguish us from generic suppliers, allowing us to meet the unique needs of our clients with precision and efficiency.

How do fire proof zippers contribute to workplace safety?

Fire proof zippers contribute significantly to workplace safety by preventing garment failure in high-temperature or fire-prone environments. They ensure protective clothing remains intact, reducing the risk of burns or injuries to workers and enabling them to perform their duties with greater confidence. As leaders in supplying fire proof zippers, we provide robust safety solutions that help create safer workplaces across various industries, aligning with occupational safety regulations and enhancing employee protection.

What role does quality control play in zipper manufacturing?

Quality control is a vital aspect of zipper manufacturing, ensuring each product meets the required standards for performance and safety. Our rigorous testing processes encompass material selection, production consistency, and final product inspection, guaranteeing the reliability of our fire proof zippers. As a supplier dedicated to excellence, our quality control measures eliminate defects and enhance customer satisfaction, reinforcing our commitment to delivering superior safety products.

How are fire proof zippers evolving with industry demands?

Fire proof zippers are continually evolving to meet industry demands by incorporating new materials that offer enhanced fire resistance, flexibility, and durability. We respond to market needs by engaging in ongoing research and development, ensuring our products address emerging safety challenges and trends. By staying ahead of industry requirements, we maintain our position as a leading supplier, offering innovative and effective solutions that fulfill our clients' safety and performance expectations.

Image Description

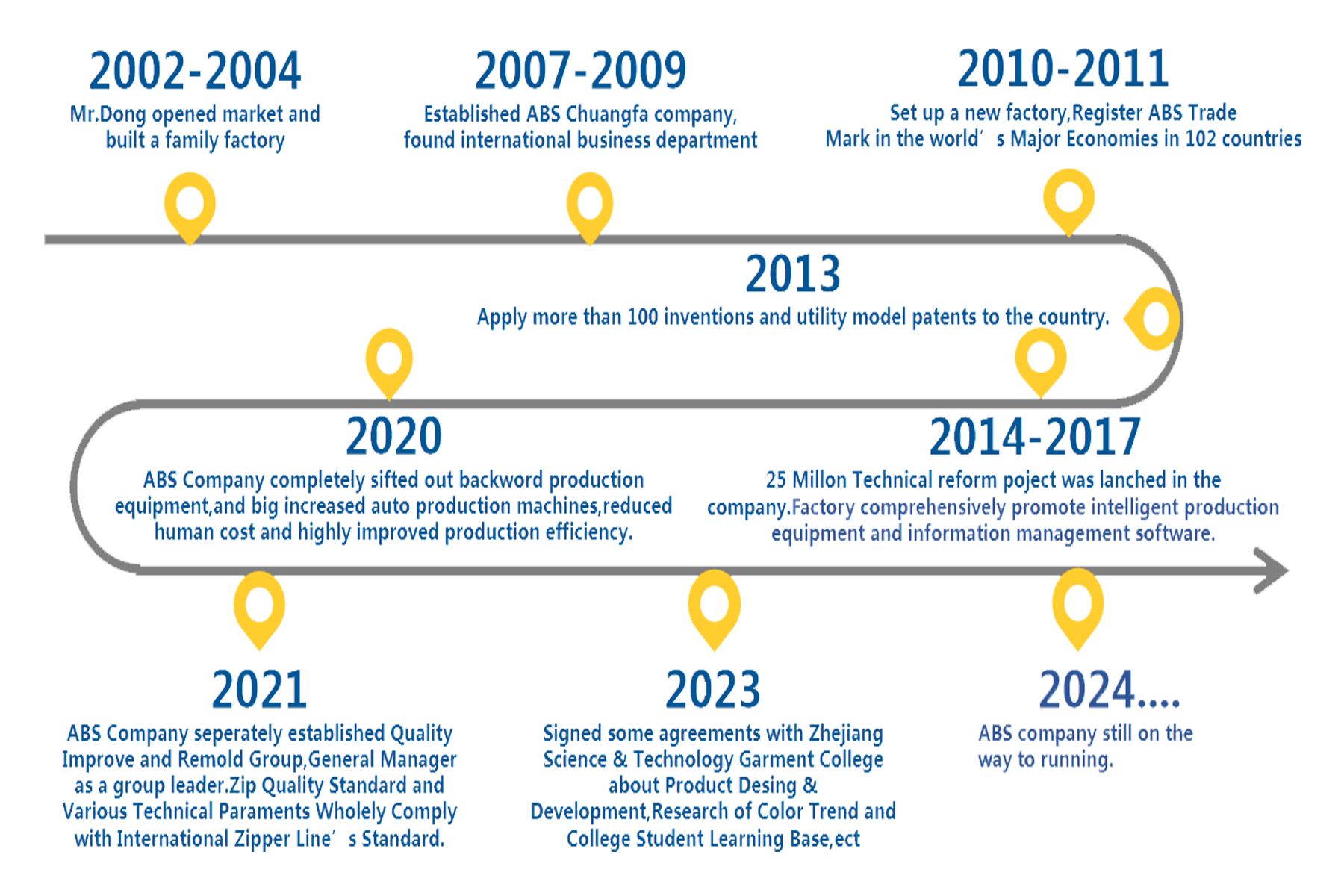

ABS Company Introduction

ABS Zhejiang Chuangfa Zipper Technology Co., LTD. was founded in 2011,which is a professional company engaged in production,sale and service of Zippers and Buttons for more than 10 years.Our Factory located in Zhejiang Haining Industrial Zone,which beside Hangzhou and enjoy very convenient transportation--15 minutes to the railway station,60 minutes to Hangzhou Airport.Our main products are Zippers,buttons and hardware parts which are exported to worldwide,such as South and North America,Europe,Southeast and Africa.Our company brand--ABS is very famous at home and abroad.We registered trademark brand ABS in 102 countries.The scope of our product using is worldwide,which suitable for clothing,shoes and hats,bags,sofa,bedding,tents,sleeping bag,umbrella,travel supplies etc.

We welcome OEM and ODM orders.Our Intelligent production equipment to ensure the effectiveness of production,product quality to reach the European and American Standard. We fully integrates the current Internet thinking concept, integrates the resources of clothing colleges with creative and design institutions, and keeps the leading position in the zipper industry field through continuous innovation of products and services. It is a modern enterprise guided by the concept of win-win cooperation and mutual development.

Our Company Slogan is “Customer first,Brand first and Service first.”

Question 1 Has your factory been audited by any organizations or institutions?

Answer Yes.We have passed the certification of GB/T19001-2016 idt ISO9001:2015,OEKO-TEX100, GRS and TUV Factory Adult.

Question 2 How long does it take to get any feedback after submitting an enquiry?

Answer In general, we will get back to you within 12 hours on weekdays.

Question 3 What are the factors that will determine the quotation?

Answer The quotation depends on a variety of factors, inclusive of the materials, quantities, tapes, slider types, the techniques involved and so forth. Please inform us of your requirements in detail when you submit an enquiry so we could offer you the best quotation.

Question 4 What are your payment terms?

Answer L/C, T/T, PayPal and West Union are all acceptable to us .Please double check with us if you would like to change the payment method.

Question 5 Can you accept any customized design?

Answer Yes. Customized/custom-made design is acceptable, including the custom-made sliders/pullers/teeth, teeth colors, tapes with mixed colors,customized textures,custom buttons,etc.

Question 6 Can we customize the colors or sizes and print our own logo?

Answer Yes. Customized colors or sizes are acceptable. As for colors, Pantone Color Card, GCC Color Card, Taiwan Color Card are available for you to choose from. Additionally, we can design and print your logo as per your request.

Question 7 Can we request for a free sample?

Answer Regular samples can always be provided free of charge if they are available in stock.If not, additional sample/mould fees will be charged to proceed with the production. Customers are supposed to bear the freight charge, which can be refunded following the order confirmation when applicable. Please double check with us.

Question 8 What’s your average lead-time? How long will it take to receive our order?

Answer Generally speaking, samples take 3-5 days while 10-15 days is required for mass production upon confirmation of the order, plus the time required for shipment/delivery. As for the metal zippers used for jeans, mass production takes less than 10 days.

Question 9 What’s your manner of packing?

Answer Based on the international packing standards, the packing manners may vary from customer to customer. We will try our best to meet your requirements so long as they conform to the conventional packing methods

Question 10 How about Price Terms and Delivery?

Answer There are a lot of choices available, including FOB Shanghai/Ningbo, CNF, CIF, etc. Generally speaking, DDP will be applied to large orders, while FEDEX, UPS, DHL, TNT and EMS are applicable to small orders.