Custom Plastic Zipper Manufacturers: 3# Metal Y Teeth

Product Main Parameters

| Product Type | Zippers |

|---|---|

| Material | Metal |

| Use | Bags, Garments, Home Textile, Shoes, Travel Set |

| Brand Name | ABS |

| Usage | Widely Used |

| Color | Customised |

| Logo | Customised |

| Puller | Customised |

| Teeth Color | Y Teeth |

| Size | Customised |

| Length | Customised |

| Sample | Free (Freight Collect) |

| Zipper Type | Open-end |

Common Product Specifications

| Type | Coil, Molded, Invisible |

|---|---|

| Flexibility | High |

| Corrosion Resistance | Yes |

| Weight | Lightweight |

Product Manufacturing Process

The manufacturing process of custom plastic zippers involves several stages crucial for ensuring product quality and functionality. Initial stages include material selection, where high-grade nylon or polyester is chosen for coil zippers due to their flexibility and strength. For molded zippers, high-strength plastic compounds are utilized, providing them with robust characteristics. In the tooth formation stage, coil zippers are produced by spiraling nylon or polyester filaments, while molded zippers are created by injecting preheated plastic into molds to form teeth. The tape production involves weaving durable textile materials like polyester. In the assembly stage, teeth are sewn onto the tape for coil zippers, whereas molded zippers see the teeth directly molded onto the tape. Finally, finishing touches include cutting zippers to required lengths and attaching sliders. Stringent quality control ensures operational smoothness and defect-free products.

Product Application Scenarios

Custom plastic zippers find extensive application across diverse industries, significantly enhancing the functionality and aesthetic appeal of various products. In the fashion and apparel sector, these zippers are integral in items ranging from casual wear to high-end fashion, providing convenience and style. The outdoor equipment industry benefits from the durability and weather resistance of plastic zippers, making them ideal for tents, backpacks, and sleeping bags. Luggage and travel accessories rely on these zippers for secure closure and ease of use, while the automotive industry uses them in seat covers for easy maintenance. The furniture sector employs plastic zippers in cushions and upholstery, allowing for hassle-free cleaning and upkeep. Their versatility is unmatched, catering to both functionality and design requirements across different domains.

Product After-Sales Service

Our after-sales service includes a comprehensive warranty, responsive customer support, and an easy return policy. Should any issue arise with your custom plastic zippers, our dedicated team is available 24/7 to assist with troubleshooting, replacement, or refund processes.

Product Transportation

We ensure secure and timely transportation of our custom plastic zippers. Utilizing reputable logistics partners, we provide global shipping options tailored to our clients' schedules and needs.

Product Advantages

- Durability: Offers high resistance against wear and tear.

- Customization: Our plastic zippers can be customized to meet specific needs.

- Lightweight: Provides a weight advantage in product design.

- Rust Resistance: Ideal for outdoor and marine applications.

- Versatility: Suitable for a wide array of products and industries.

Product FAQ

- 1. What materials are used in your custom plastic zippers?

We utilize high-quality nylon and polyester for coil zippers, and robust plastic compounds for molded zippers, ensuring longevity and reliability. - 2. Can I order custom lengths for bulk orders?

Yes, we offer customized lengths for bulk orders to meet specific customer requirements. - 3. Are these zippers suitable for outdoor use?

Absolutely, our custom plastic zippers are designed to withstand harsh environmental conditions, making them ideal for outdoor applications. - 4. How do you ensure the quality of your zippers?

We employ advanced testing equipment and a rigorous QC process, checking each product individually to maintain high quality standards. - 5. What is the typical lead time for custom orders?

The lead time varies depending on the order size, but generally ranges from 2 to 4 weeks. - 6. Are samples available for new customers?

Yes, we provide samples for new customers, allowing them to assess quality before placing a bulk order. - 7. How are the products packaged for shipping?

Our products are packaged securely, with careful consideration to prevent damage during transportation. - 8. Do you offer eco-friendly zipper options?

Yes, we are committed to sustainability and offer zippers made from recycled materials. - 9. Can the color and logo be customized?

Yes, we offer customization options for both color and logo to align with your brand specifications. - 10. What industries do your zippers primarily serve?

Our zippers cater to various industries, including fashion, outdoor gear, luggage, automotive, and furniture.

Product Hot Topics

- 1. Durability of Custom Plastic Zippers:

Custom plastic zipper manufacturers are renowned for producing zippers that offer exceptional durability. These zippers are designed to endure the rigors of daily use, making them ideal for a variety of applications. The choice of high-grade materials ensures resistance against wear and tear, while advanced manufacturing processes enhance their longevity. For industries requiring robust fastening solutions, these zippers provide an unbeatable combination of strength and reliability, supporting both functional and aesthetic needs. - 2. Innovations in Custom Plastic Zipper Manufacturing:

The realm of custom plastic zipper manufacturing is constantly evolving, with new innovations enhancing product quality and functionality. Recent advancements include the use of sustainable materials, such as recycled plastics, addressing environmental concerns and fulfilling consumer demands for eco-friendly products. Manufacturers are also employing cutting-edge technology to improve zipper design, ensuring better resistance to environmental factors and increased ease of use. These innovations highlight the industry's commitment to meeting market needs while steering towards sustainability. - 3. Customization Options in Plastic Zippers:

Custom plastic zipper manufacturers offer extensive customization options to meet specific client requirements. From varying color palettes and unique logo imprints to specific length and size adaptations, manufacturers cater to diverse industry demands. This flexibility ensures that zippers not only fulfill functional requirements but also align with brand aesthetics, enabling businesses to enhance their product appeal. As consumer preferences continue to evolve, customization remains a pivotal factor in the zipper industry. - 4. Environmental Responsibility in Zipper Manufacturing:

In an era of heightened environmental awareness, custom plastic zipper manufacturers are increasingly adopting sustainable practices. This includes utilizing eco-friendly materials such as biodegradable compounds and recycled plastics. Such initiatives demonstrate the industry's commitment to minimizing its environmental footprint, while still delivering high-quality products. As consumers prioritize sustainability, these practices set manufacturers apart in the competitive market. - 5. The Role of Quality Control in Zipper Production:

Quality control is a cornerstone of custom plastic zipper manufacturing, ensuring each product meets rigorous standards before reaching the market. This process includes thorough inspection and testing at various production stages, from material selection to final assembly. By maintaining high quality benchmarks, manufacturers build trust with consumers, reinforcing their confidence in the product's reliability and performance. - 6. Addressing Market Demands for Custom Zippers:

Custom plastic zipper manufacturers are adept at responding to market trends and demands. With an increasing focus on personalization, manufacturers offer bespoke solutions tailored to individual consumer preferences and industry needs. This ability to adapt positions manufacturers as leaders in the market, capable of providing products that complement current fashion and functional trends. - 7. Cost-Effectiveness of Using Plastic Zippers:

Choosing custom plastic zippers is a cost-effective solution for many businesses, offering a balance between affordability and quality. The lightweight nature of plastic zippers results in lower transportation costs, while their versatility makes them suitable for a variety of applications. This economic advantage without compromising on performance makes them a preferred choice across industries. - 8. The Impact of Technology on Zipper Manufacturing:

Technology plays a crucial role in the evolution of custom plastic zipper manufacturing. Advanced machinery and automation streamline production processes, enhancing efficiency and precision. This technological integration not only boosts productivity but also ensures consistent quality, allowing manufacturers to meet high-volume demands while maintaining excellence. - 9. Challenges Facing the Zipper Industry:

The custom plastic zipper industry faces challenges such as fluctuating raw material costs and environmental concerns. To combat these, manufacturers are innovating with alternative materials and adopting eco-friendly production practices. By addressing these challenges proactively, the industry continues to thrive, meeting consumer demands while ensuring sustainable growth. - 10. The Future of Custom Plastic Zipper Manufacturing:

The future of custom plastic zipper manufacturing is promising, with an emphasis on sustainability and innovation. As technological advancements continue to shape the industry, manufacturers are poised to deliver even more efficient and environmentally conscious products. The focus on customization and consumer-centric solutions will further drive the industry's growth, ensuring its relevance in a dynamic market landscape.

Image Description

There is no picture description for this product

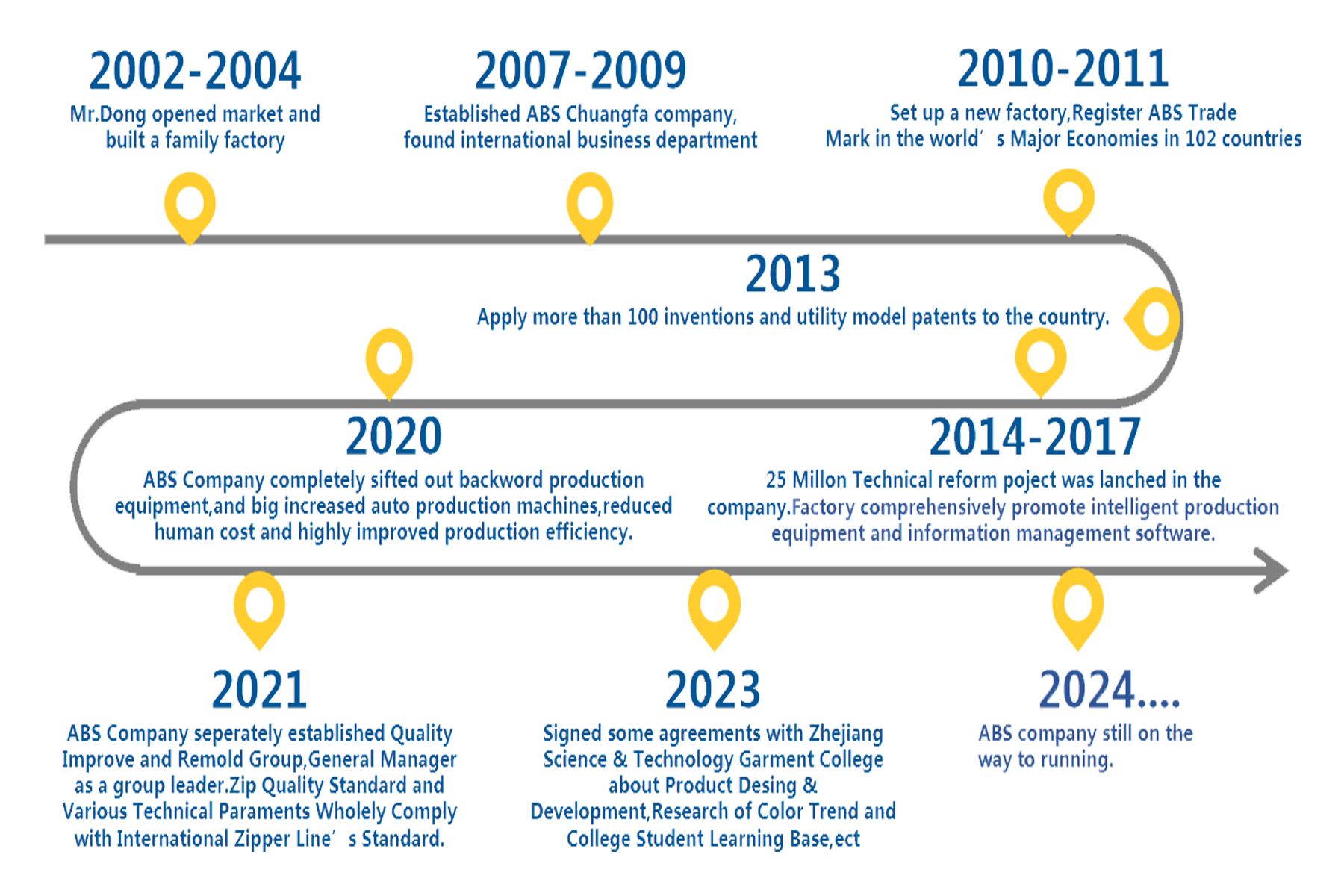

ABS Company Introduction

ABS Zhejiang Chuangfa Zipper Technology Co., LTD. was founded in 2011,which is a professional company engaged in production,sale and service of Zippers and Buttons for more than 10 years.Our Factory located in Zhejiang Haining Industrial Zone,which beside Hangzhou and enjoy very convenient transportation--15 minutes to the railway station,60 minutes to Hangzhou Airport.Our main products are Zippers,buttons and hardware parts which are exported to worldwide,such as South and North America,Europe,Southeast and Africa.Our company brand--ABS is very famous at home and abroad.We registered trademark brand ABS in 102 countries.The scope of our product using is worldwide,which suitable for clothing,shoes and hats,bags,sofa,bedding,tents,sleeping bag,umbrella,travel supplies etc.

We welcome OEM and ODM orders.Our Intelligent production equipment to ensure the effectiveness of production,product quality to reach the European and American Standard. We fully integrates the current Internet thinking concept, integrates the resources of clothing colleges with creative and design institutions, and keeps the leading position in the zipper industry field through continuous innovation of products and services. It is a modern enterprise guided by the concept of win-win cooperation and mutual development.

Our Company Slogan is “Customer first,Brand first and Service first.”

Question 1 Has your factory been audited by any organizations or institutions?

Answer Yes.We have passed the certification of GB/T19001-2016 idt ISO9001:2015,OEKO-TEX100, GRS and TUV Factory Adult.

Question 2 How long does it take to get any feedback after submitting an enquiry?

Answer In general, we will get back to you within 12 hours on weekdays.

Question 3 What are the factors that will determine the quotation?

Answer The quotation depends on a variety of factors, inclusive of the materials, quantities, tapes, slider types, the techniques involved and so forth. Please inform us of your requirements in detail when you submit an enquiry so we could offer you the best quotation.

Question 4 What are your payment terms?

Answer L/C, T/T, PayPal and West Union are all acceptable to us .Please double check with us if you would like to change the payment method.

Question 5 Can you accept any customized design?

Answer Yes. Customized/custom-made design is acceptable, including the custom-made sliders/pullers/teeth, teeth colors, tapes with mixed colors,customized textures,custom buttons,etc.

Question 6 Can we customize the colors or sizes and print our own logo?

Answer Yes. Customized colors or sizes are acceptable. As for colors, Pantone Color Card, GCC Color Card, Taiwan Color Card are available for you to choose from. Additionally, we can design and print your logo as per your request.

Question 7 Can we request for a free sample?

Answer Regular samples can always be provided free of charge if they are available in stock.If not, additional sample/mould fees will be charged to proceed with the production. Customers are supposed to bear the freight charge, which can be refunded following the order confirmation when applicable. Please double check with us.

Question 8 What’s your average lead-time? How long will it take to receive our order?

Answer Generally speaking, samples take 3-5 days while 10-15 days is required for mass production upon confirmation of the order, plus the time required for shipment/delivery. As for the metal zippers used for jeans, mass production takes less than 10 days.

Question 9 What’s your manner of packing?

Answer Based on the international packing standards, the packing manners may vary from customer to customer. We will try our best to meet your requirements so long as they conform to the conventional packing methods

Question 10 How about Price Terms and Delivery?

Answer There are a lot of choices available, including FOB Shanghai/Ningbo, CNF, CIF, etc. Generally speaking, DDP will be applied to large orders, while FEDEX, UPS, DHL, TNT and EMS are applicable to small orders.