Custom 15# Triangle Teeth Zip Fastener Manufacturers

Product Main Parameters

| Material | Resin |

|---|---|

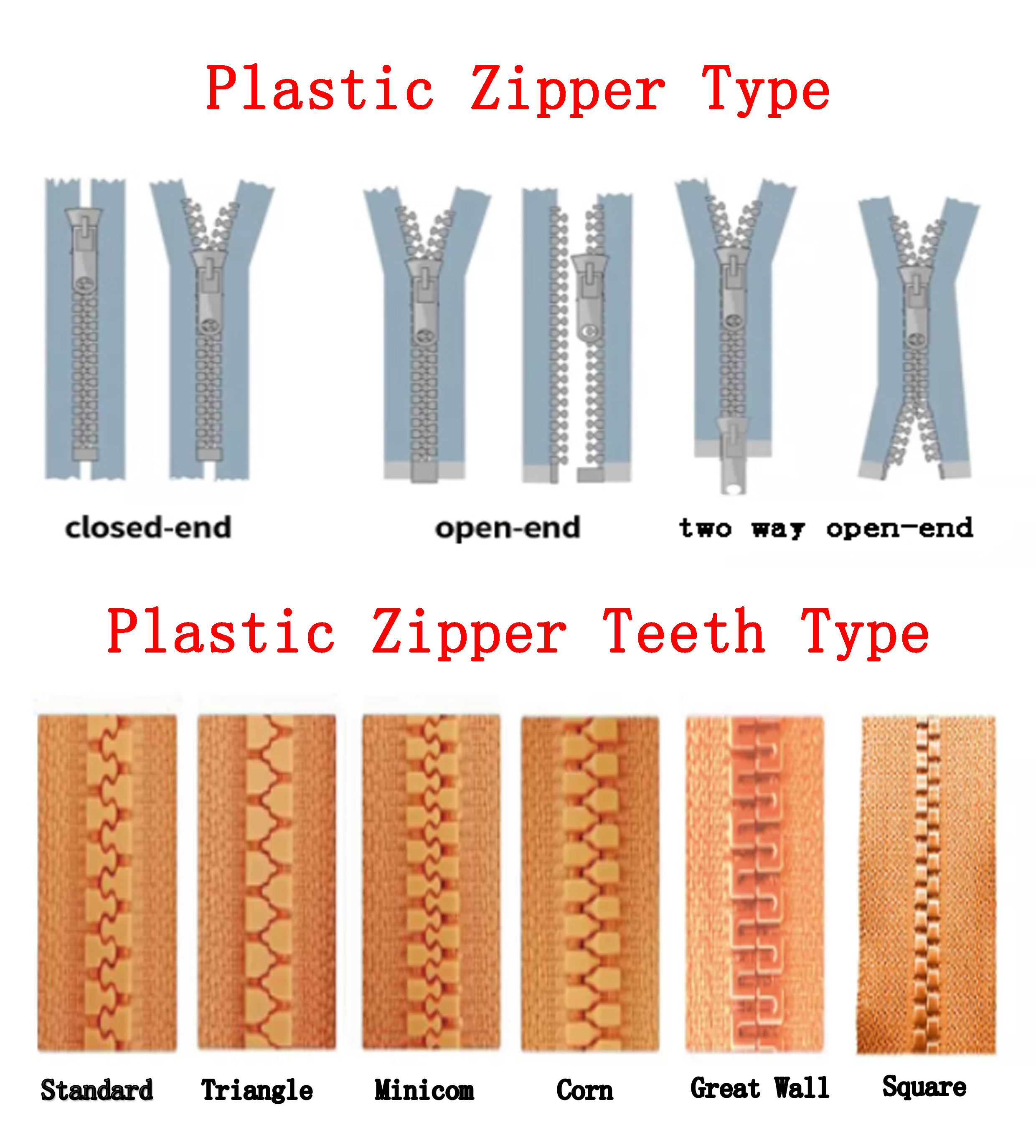

| Teeth | Triangle |

| Color | Beige |

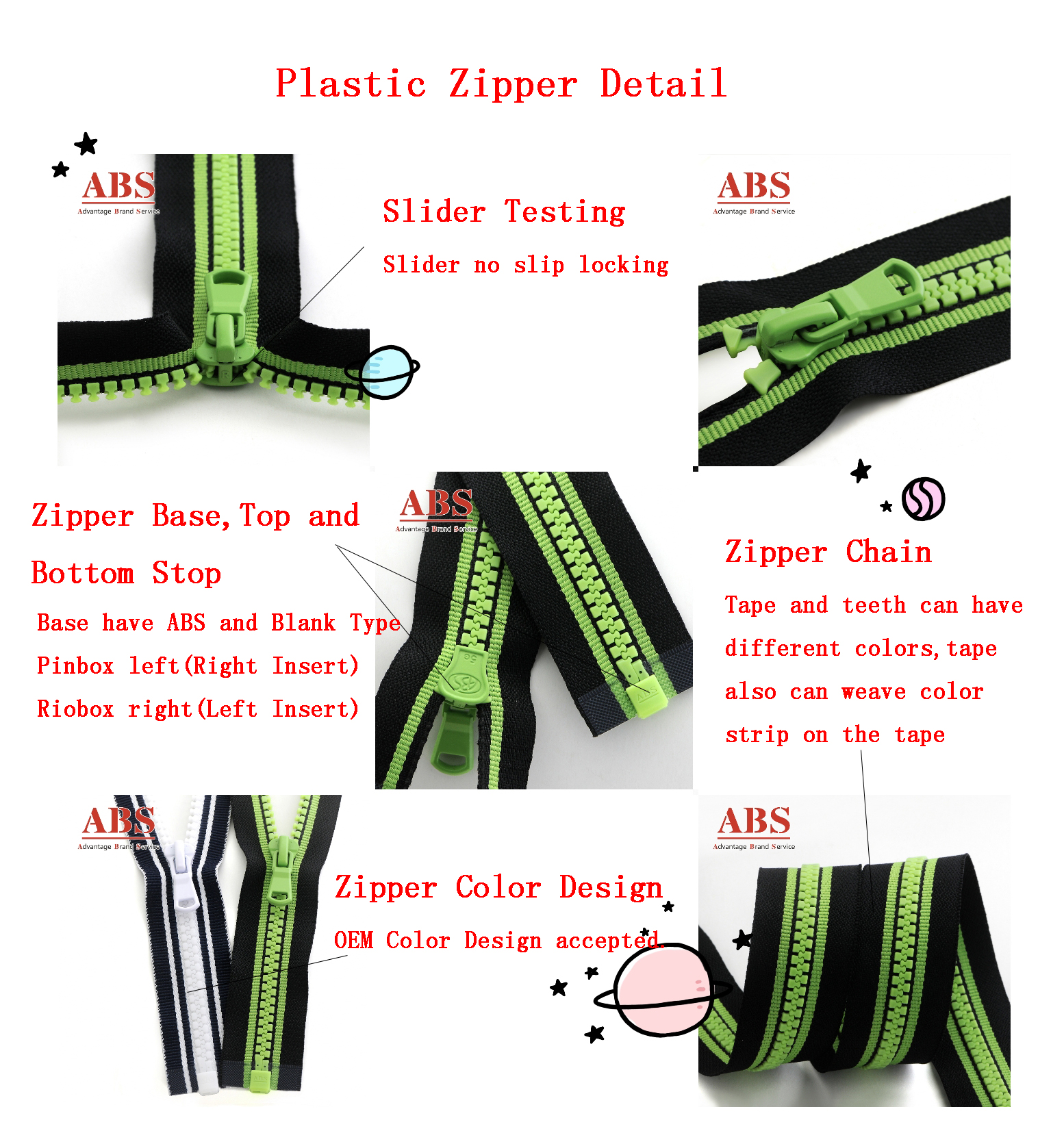

| Slider | Auto-Lock |

| Length | Custom |

| MOQ | 1000 pcs |

| Certification | OEKO-TEX 100, GRS, ISO |

Common Product Specifications

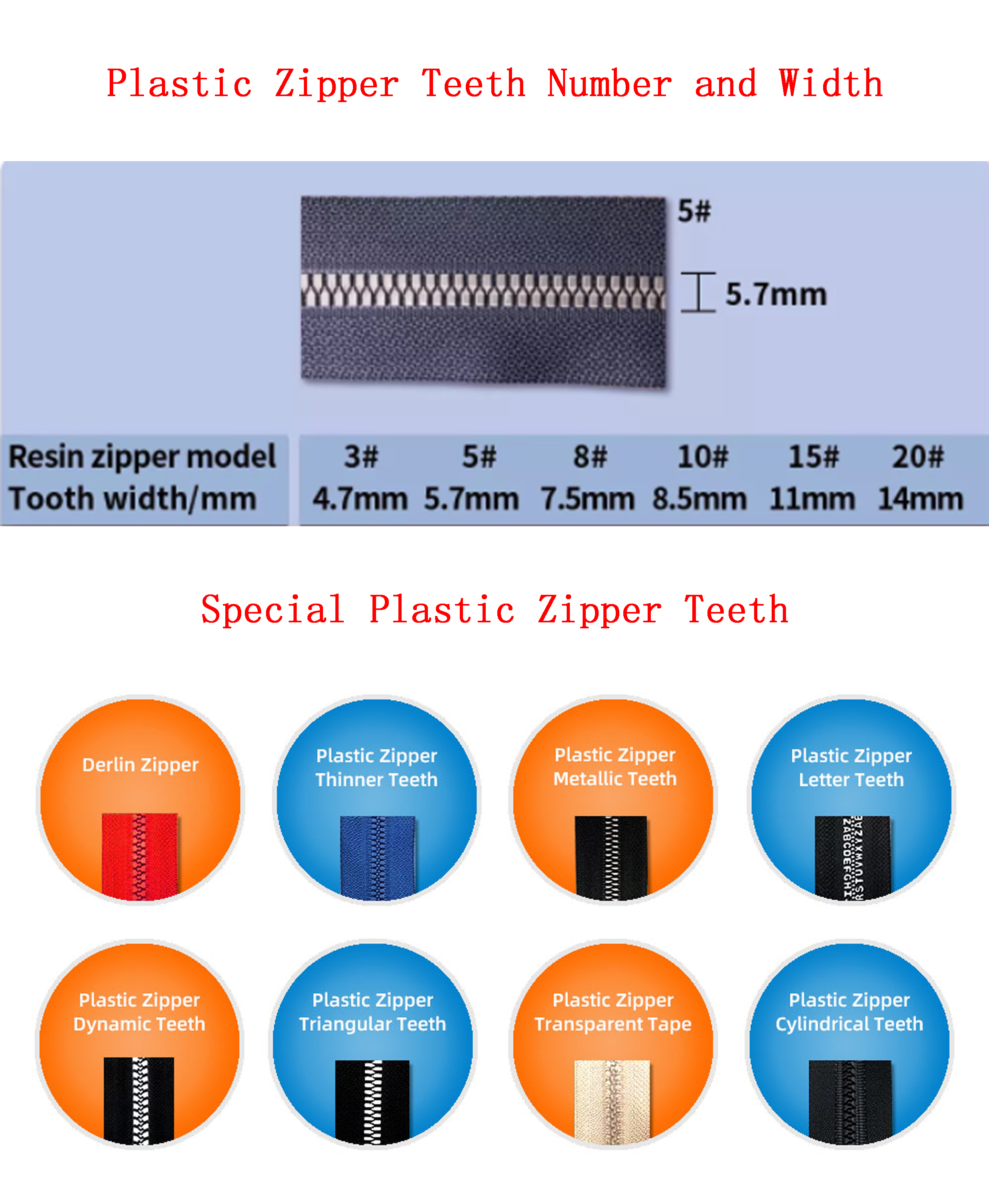

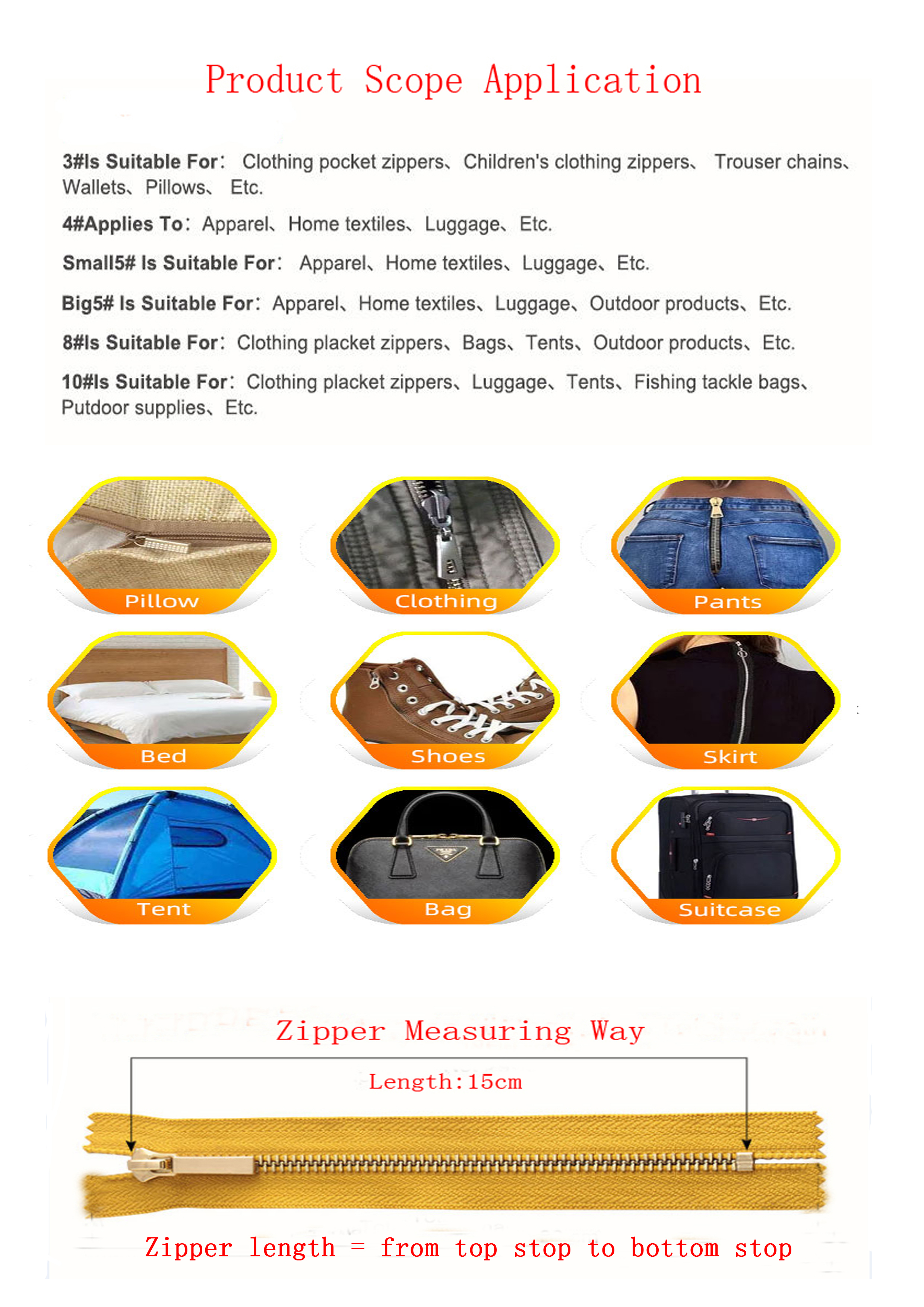

| Zip Types | 3#, 5#, 8#, 10#, 15#, 20# |

|---|---|

| Teeth Types | Normal, Corn, Dynamic |

Product Manufacturing Process

The manufacturing process of zippers has evolved significantly over the years. Initially, manufacturers focus on design and development, working closely with fashion designers to meet specific requirements in terms of strength and aesthetics. Material selection plays a crucial role in ensuring durability; common materials include metal, nylon, and plastic. The production process involves forming the zipper chain and adding sliders and stops, with modern machines automating much of the work to ensure precision and efficiency. Quality control is paramount; each zipper undergoes rigorous testing for strength, smoothness, and reliability. Customization options, such as color, length, and branding, are available to meet individual client specifications. As influential figures like Sundback revolutionized zipper technology, today’s manufacturers continue to innovate, ensuring zippers not only meet but exceed industry standards.

Product Application Scenarios

Zippers are an essential component across a wide variety of applications. In the fashion industry, they serve as closures for garments such as jackets, casual clothes, knitted sweaters, and fashion coats, providing both functionality and aesthetic appeal. Beyond fashion, zippers are used in bags, sofa covers, bedding, tents, sleeping bags, umbrellas, and even travel supplies. Their versatility extends to heavy-duty applications with metal zippers for jeans and workwear, while waterproof zippers are prevalent in outdoor gear and equipment. As innovations in zip fastener technology continue, manufacturers are developing zippers with enhanced functionalities, such as fire resistance and antibacterial properties, further broadening their range of application scenarios.

Product After-Sales Service

We offer a robust after-sales service, including free repair or replacement within one year. Our dedicated support team is available 24/7 to assist with any inquiries or issues, ensuring complete customer satisfaction.

Product Transportation

We provide fast delivery times worldwide. Products can be dispatched within 7-10 days of order confirmation, utilizing reliable logistics partners for secure and timely shipping.

Product Advantages

- OEM/ODM Support

- Customization Options

- Compliant with OEKO-TEX 100 Standards

- Affordable Pricing

- High Quality and Durable

Product FAQ

- What materials are your zippers made of?

Our zippers are crafted from high-quality resin, ensuring both durability and flexibility. Custom materials are available upon request.

- What payment methods do you accept?

We accept various payment methods including Paypal, Sight L/C, T/T, West Union, and Credit Card for the convenience of our customers.

- Can I order a small quantity?

Yes, we accept small orders with a minimum order quantity of 1000 pieces, making it easier for small businesses to collaborate with us.

- How long does delivery take?

Our typical delivery time ranges from 7 to 10 days, depending on the order size and customization requirements.

- Are your products environmentally friendly?

Yes, our products are designed with sustainability in mind, complying with OEKO-TEX 100 standards to ensure minimal environmental impact.

- Do you offer customization services?

Absolutely, we provide comprehensive customization services, including color, length, and branding to meet specific client needs.

- How do you ensure product quality?

Our zippers go through rigorous quality control processes, including advanced testing for strength and reliability, to ensure they meet the highest standards.

- What industries do your zippers serve?

Our zippers are versatile, serving numerous industries such as fashion, outdoor equipment, travel goods, and more.

- Do you offer design and development support?

Yes, we collaborate closely with designers to develop products that meet specific aesthetic and functional needs.

- What sets you apart from other zipper manufacturers?

Our commitment to innovation, comprehensive customization options, and exceptional customer service distinguish us as leaders in the zip fastener manufacturing industry.

Product Hot Topics

- How Customized Zippers are Transforming the Fashion Industry

The fashion industry thrives on uniqueness and individuality. Custom zippers play a pivotal role in this transformation by allowing designers to experiment with colors, materials, and styles that align with their brand's aesthetic. Zip fastener manufacturers like ABS Zipper are at the forefront of this innovation, providing tailored solutions that cater to the diverse needs of designers, ultimately revolutionizing the way garments and accessories are designed and perceived.

- The Environmental Impact of Zipper Manufacturing

As environmental concerns grow, the zipper manufacturing industry is taking significant steps toward sustainability. By adopting eco-friendly materials and production methods, zip fastener manufacturers are reducing their carbon footprint and ensuring that their products comply with stringent environmental standards. This shift not only benefits the planet but also aligns with consumer demand for sustainable fashion and accessories.

- Innovative Technologies in Zipper Manufacturing

Technological advancements are reshaping the zipper manufacturing landscape. From automated production lines to digitally integrated design processes, manufacturers are leveraging technology to enhance efficiency and precision. These innovations allow for greater customization capabilities, enabling zip fastener manufacturers to deliver products that meet the evolving needs of the market with unmatched quality and speed.

- The Role of Zippers in Outdoor Gear

Outdoor gear relies heavily on robust and reliable fastening solutions, making zippers an integral component. Custom zippers designed for outdoor applications offer enhanced features such as waterproofing, UV resistance, and increased durability. Zip fastener manufacturers specialize in creating products that withstand harsh conditions, ensuring the safety and comfort of outdoor enthusiasts worldwide.

- Customization Trends in Zip Fastener Manufacturing

Customization is more than a trend; it's a necessity in today's competitive market. Zip fastener manufacturers are embracing this by offering tailored solutions that allow clients to specify every aspect of their zippers, from color to material. This trend reflects a broader movement towards personalized products in various industries, enabling brands to stand out in a crowded marketplace.

- Quality Control in Zipper Production

Ensuring the quality and reliability of zippers is paramount. Zip fastener manufacturers implement stringent quality control measures, including advanced testing for strength and durability. This commitment to quality ensures that their products not only meet but exceed industry standards, providing clients with dependable solutions for various applications.

- The Global Reach of Zipper Manufacturers

With the expansion of international markets, zip fastener manufacturers are positioning themselves as global players. By establishing a presence in key regions and adapting to diverse market demands, manufacturers like ABS Zipper are able to offer exceptional service and support to clients worldwide, enhancing their global reach and reputation.

- The Future of Zip Fasteners

Looking ahead, the future of zippers lies in innovation and sustainability. Zip fastener manufacturers are investing in research and development to create products with advanced functionalities, such as fire resistance and antimicrobial properties. By prioritizing sustainable practices, these manufacturers are shaping the future of fastening solutions in a rapidly changing world.

- Zip Fastener Manufacturers and Industry Partnerships

The success of zip fastener manufacturers often hinges on collaborations with industry partners. By working closely with fashion designers, outdoor brands, and other stakeholders, manufacturers are able to deliver customized solutions that align with specific market needs. These partnerships foster innovation and drive the development of new and exciting products.

- Zip Fasteners in the Age of Sustainability

The demand for sustainable products is reshaping the zipper industry. Zip fastener manufacturers are responding by adopting eco-friendly materials and processes, ensuring their products meet environmental standards. This commitment to sustainability not only benefits the planet but also aligns with the values of today’s conscientious consumers, paving the way for a more sustainable future.

Image Description

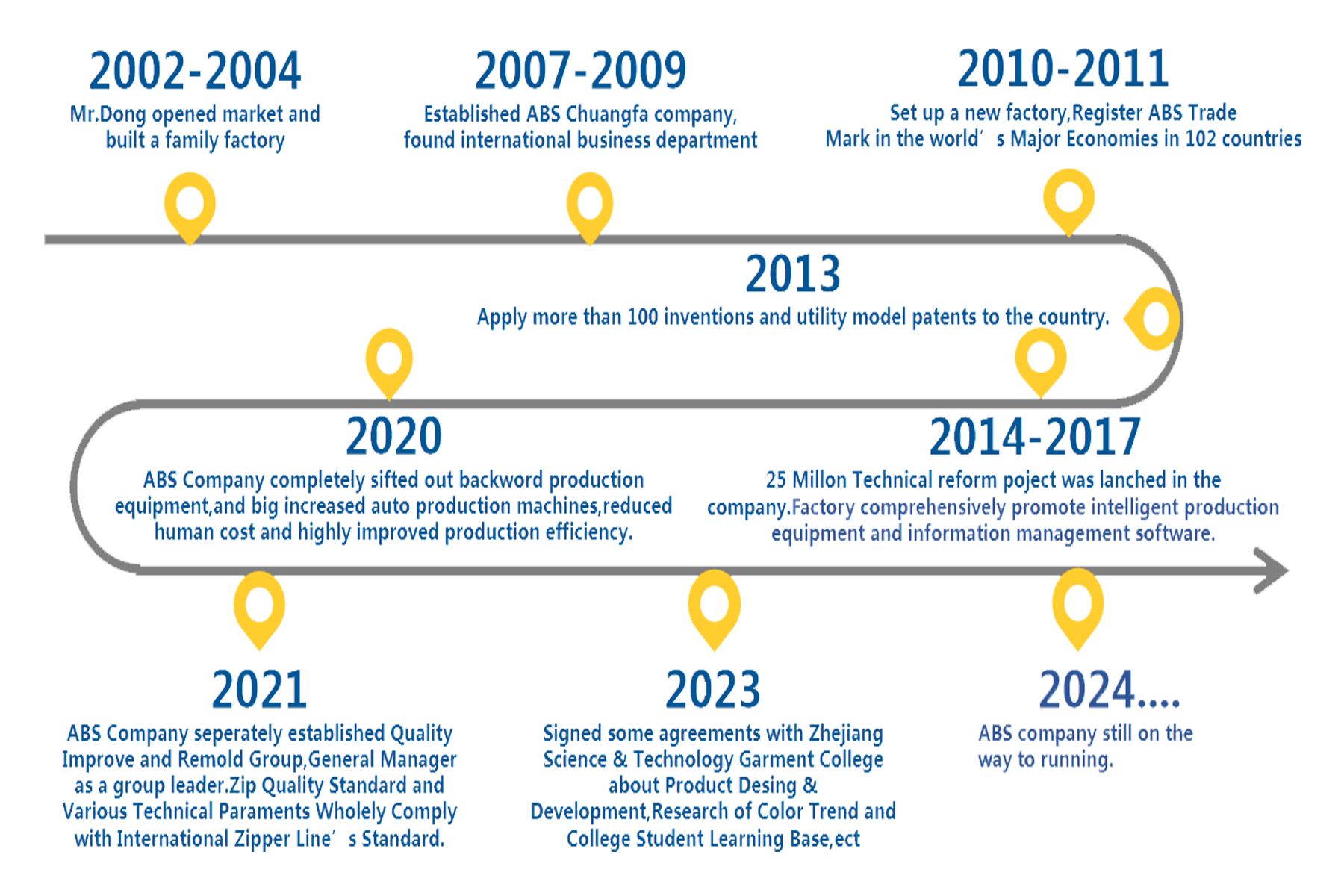

ABS Company Introduction

ABS Zhejiang Chuangfa Zipper Technology Co., LTD. was founded in 2011,which is a professional company engaged in production,sale and service of Zippers and Buttons for more than 10 years.Our Factory located in Zhejiang Haining Industrial Zone,which beside Hangzhou and enjoy very convenient transportation--15 minutes to the railway station,60 minutes to Hangzhou Airport.Our main products are Zippers,buttons and hardware parts which are exported to worldwide,such as South and North America,Europe,Southeast and Africa.Our company brand--ABS is very famous at home and abroad.We registered trademark brand ABS in 102 countries.The scope of our product using is worldwide,which suitable for clothing,shoes and hats,bags,sofa,bedding,tents,sleeping bag,umbrella,travel supplies etc.

We welcome OEM and ODM orders.Our Intelligent production equipment to ensure the effectiveness of production,product quality to reach the European and American Standard. We fully integrates the current Internet thinking concept, integrates the resources of clothing colleges with creative and design institutions, and keeps the leading position in the zipper industry field through continuous innovation of products and services. It is a modern enterprise guided by the concept of win-win cooperation and mutual development.

Our Company Slogan is “Customer first,Brand first and Service first.”

Question 1 Has your factory been audited by any organizations or institutions?

Answer Yes.We have passed the certification of GB/T19001-2016 idt ISO9001:2015,OEKO-TEX100, GRS and TUV Factory Adult.

Question 2 How long does it take to get any feedback after submitting an enquiry?

Answer In general, we will get back to you within 12 hours on weekdays.

Question 3 What are the factors that will determine the quotation?

Answer The quotation depends on a variety of factors, inclusive of the materials, quantities, tapes, slider types, the techniques involved and so forth. Please inform us of your requirements in detail when you submit an enquiry so we could offer you the best quotation.

Question 4 What are your payment terms?

Answer L/C, T/T, PayPal and West Union are all acceptable to us .Please double check with us if you would like to change the payment method.

Question 5 Can you accept any customized design?

Answer Yes. Customized/custom-made design is acceptable, including the custom-made sliders/pullers/teeth, teeth colors, tapes with mixed colors,customized textures,custom buttons,etc.

Question 6 Can we customize the colors or sizes and print our own logo?

Answer Yes. Customized colors or sizes are acceptable. As for colors, Pantone Color Card, GCC Color Card, Taiwan Color Card are available for you to choose from. Additionally, we can design and print your logo as per your request.

Question 7 Can we request for a free sample?

Answer Regular samples can always be provided free of charge if they are available in stock.If not, additional sample/mould fees will be charged to proceed with the production. Customers are supposed to bear the freight charge, which can be refunded following the order confirmation when applicable. Please double check with us.

Question 8 What’s your average lead-time? How long will it take to receive our order?

Answer Generally speaking, samples take 3-5 days while 10-15 days is required for mass production upon confirmation of the order, plus the time required for shipment/delivery. As for the metal zippers used for jeans, mass production takes less than 10 days.

Question 9 What’s your manner of packing?

Answer Based on the international packing standards, the packing manners may vary from customer to customer. We will try our best to meet your requirements so long as they conform to the conventional packing methods

Question 10 How about Price Terms and Delivery?

Answer There are a lot of choices available, including FOB Shanghai/Ningbo, CNF, CIF, etc. Generally speaking, DDP will be applied to large orders, while FEDEX, UPS, DHL, TNT and EMS are applicable to small orders.